Computer programs are used in CNC machining to design the process flow that the machine tool will follow. The machine tools are inaccessible to users directly, hence computer-aided design (CAD) software is utilized. The 2- and 3-dimensional models for the necessary CNC-machined parts are made using CAD software. The machine is aware of the final part's appearance thanks to its design.

CNC (Computer Numerical Control) machining is a sophisticated manufacturing process that involves the use of computerized systems to control and manipulate tools and machinery for precision cutting, shaping, and forming of materials. CNC machine tools, short for Computer Numerical Control machine tools, are advanced manufacturing systems that utilize computerized controls to automate and precisely execute various machining operations.

These tools play a pivotal role in modern manufacturing, allowing for high-precision production of intricate components used in industries such as aerospace, automotive, electronics, and medical devices. CNC Machine Tools encompass a wide range of machines, each tailored for specific tasks and materials.

Stages of CNC Machining

Preferred method in various industries, including aerospace, automotive, electronics, and medical. The process typically consists of four stages, each crucial for producing intricate and complex parts with exceptional precision.

Design and Programming

The first stage of CNC machining involves designing the part to be manufactured and creating a digital blueprint of the design. This step is crucial as it defines the specifications and dimensions of the final product. CAD (Computer-Aided Design) software is commonly used for this purpose, allowing engineers and designers to create detailed 2D or 3D models of the component.

In the programming stage, engineers and programmers create a set of instructions that guide the CNC machine's movements and actions. These instructions include details such as toolpaths, cutting speeds, feed rates, and tool changes.

Setup and Tooling

After the CNC program is created, the next stage involves setting up the CNC machine for production. This setup includes selecting the appropriate cutting tools, securing the workpiece into the machine's worktable, and loading the CNC program into the machine's control unit. Proper tool selection is critical, as different tools are required for specific machining operations, such as drilling, milling, turning, or threading.

During the setup stage, machinists carefully install and calibrate the cutting tools, ensuring they are aligned and secure. The workpiece is then securely clamped onto the machine's work table or fixture to prevent movement during machining.

Machining Operations

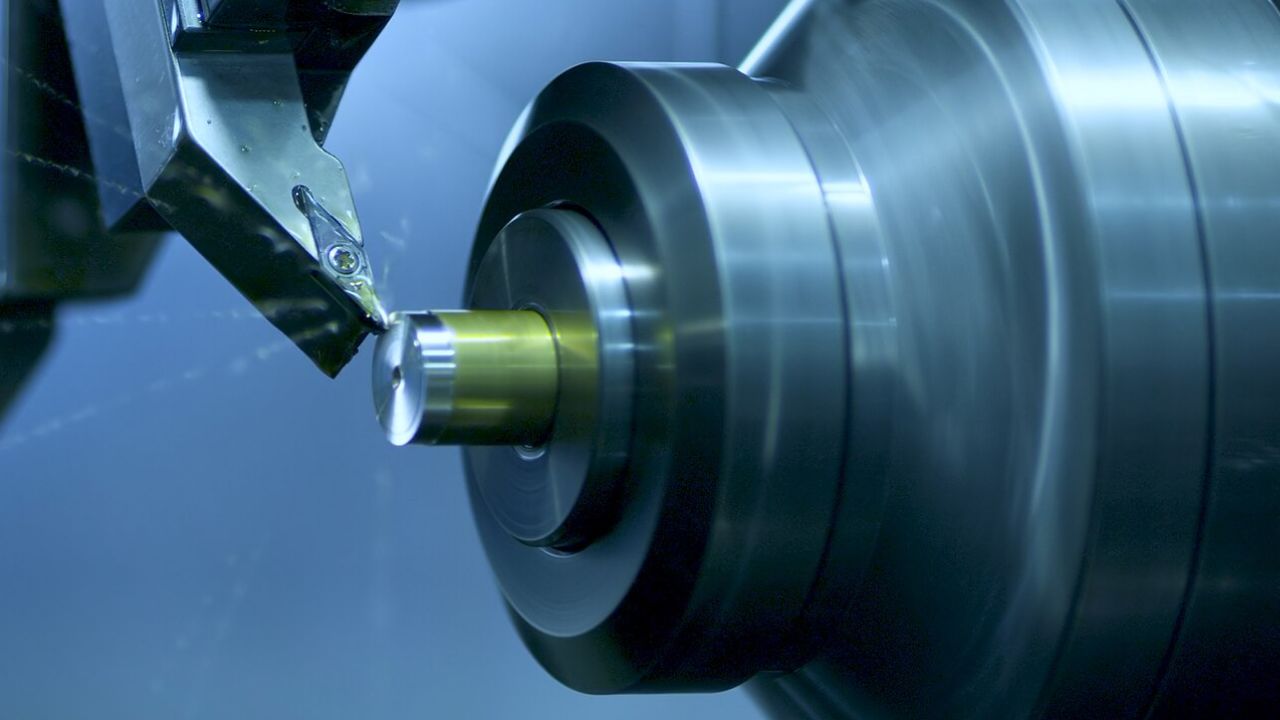

The machining operations stage is where the actual cutting and shaping of the workpiece occur. The CNC machine follows the programmed instructions to perform a series of precise movements and cuts, removing excess material and forming the final part. The machine's cutting tools rotate, move along multiple axes, and apply controlled forces to achieve the desired shape and dimensions. The choice of machining operation depends on the complexity of the part and the material being used. CNC machines can produce intricate geometries and tight tolerances, ensuring high-quality and accurate components.

Inspection and Quality Control

After the machining operations are completed, the final stage involves inspecting and quality-checking the manufactured parts. Machinists and quality control personnel use measuring instruments such as micrometers, calipers, and coordinate measuring machines (CMMs) to verify the dimensions, surface finish, and overall quality of the components. In addition to dimensional inspections, other quality checks may include visual inspections, material composition analysis, hardness testing, and functionality tests.

Summary

CNC machine tools are indispensable in modern manufacturing, offering unmatched precision, versatility, and efficiency. Their ability to handle diverse materials and perform complex operations makes them vital assets in various industries, driving innovation and enabling the production of high-quality components.